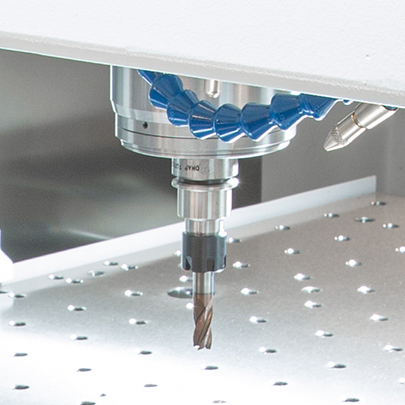

Spindle thermal drift control

This is a subject to which we have dedicated many resources in recent years. In this regard, we have modified our machines several times in order not to have, or rather to have as little as possible, hot spots inside our machines. The cooling system we use is also special and ensures that the spindle temperature follows the external temperature increased by 3º very closely.

Current situation of the spindles we produce

We have in production three models of spindles that are identified by the size of the cone spindle HSK (Hohl Schaft Kege) and more exactly:

HSK32 – very small spindle. At the level of dermal drift in the current situation we are talking about 0.02~0.03 mm. It is sufficient to wait a few minutes to have no problems.

HSK40 – medium spindle. We are talking about 0.04~0.05 mm of drift.

HSK50 – spindle with the highest power and size in our production. Easy to reach 0.07 mm of thermal drift.

Solutions adopted by other manufacturers

Thermally stabilized machine structures. Liquid is circulated throughout the machine structure. This liquid is then, we imagine, cooled or heated appropriately to minimize thermal drift of the spindle. We also imagine that there are special software modules to keep everything under control.

Spindle rotor cooling. Surely this is the most fascinating solution. The rotor of an electric spindle can reach very high temperatures. From a theoretical point of view, cancelling this heat would seem to be the best technical solution. Even the life of the spindle bearings would benefit from the elimination of the heat generated by the rotor. It is easy to imagine the technical difficulties in reaching such a solution, besides the particularly high production costs. We can also imagine that the overhaul costs of an electro spindle made with this technology are prohibitive. Also in this case we presume that there are appropriate software modules to keep the situation under control.

Solution adopted by us

The type of market we are addressing does not allow us to adopt any of the above solutions. In any case, these solutions are not only expensive but also very complex to implement. To the best of our knowledge, it has to be proved that even with the implementation of one of the two above-mentioned technologies the goal of containing the thermal drift within 0.01 mm would have been really achieved.

For the time being, we have only done our tests with our Hsk40 spindle. We imagine that with other spindle types we will also achieve proportionally similar drift values.

We have adopted particularly complex thermal drift compensation algorithms that make use of Artificial Intelligence techniques. We have also added one or more sensors with an important precision to be able to understand what is actually moving.

In order to contain the thermal drift within 0.01 mm the ambient temperature must remain unchanged or vary only very progressively. The machine cannot be placed near doors to the outside or subject to sunlight.

This kind of software can be installed not only on new machines, but also on our machines sold in the last 10 years, even if some hardware integrations will have to be made.

Limitation of liability

This software is still experimental. We reserve the right to remove all hardware/software elements in case the containment of thermal drift within 0.01 mm is not achieved. In this case any payment made by our customers for this purpose will be refunded. Indicatively only in six months we will be able to remove this limitation of liability. For the time being, we have only tested it with our Hsk40 spindle. We assume that other spindle types.

We imagine that the other spindle types will produce proportionally similar drift values.

We have adopted particularly complex thermal drift compensation algorithms that make use of Artificial Intelligence techniques. We have also added one or more sensors with an important precision to be able to understand what is actually moving.

In order to contain the thermal drift within 0.01 mm the ambient temperature must remain unchanged or vary only very progressively. The machine cannot be placed near doors to the outside or subject to sunlight.

This kind of software can be installed not only on new machines, but also on our machines sold in the last 10 years, even if some hardware integrations will have to be made.

Limitation of liability

This software is still at an experimental level. We reserve the right to remove all hardware/software elements in case the containment of thermal drift within 0.01 mm is not achieved. In this case any payment made by our customers for this purpose will be refunded. Indicatively only in six months we will be able to remove this limitation of liability. For the time being, we have only tested it with our Hsk40 spindle. We imagine that with other types.

Last Updated on 29 November 2021 by Pear